The Role of Integrated Wireless Technology in Modern Warehouse Management Systems

Handling the many activities of a typical storage depot can be a challenging task, but wireless technology can automatewarehouse management systems (WMS). Whether in a supermarket stockroom, distribution centre or anywhere where large quantities of different items are stored before sale or despatch, numerous tasks must be undertaken by those responsible for monitoring their movements.

As new stock is received, it must be checked against orders and invoices before it is appropriately located and records are updated. Similar actions are necessary to track items that have been returned or delivered to customers or retailers. Gathering, sorting, and manually recording the reams of data generated by these activities can be time-consuming and often result in human error.

Successfully operating a stockroom or warehouse is a delicate balancing act that requires foresight but which, unfortunately, is quite often based on a mix of experience and guesswork. Periodic stock takes are helpful, but the data they provide is historical. Therefore, it is fortunate that digital technology now offers a means to monitor stock movements continuously and accurately and increase overall operating efficiency.

While software developers have designed computer programmes such as accounting and enterprise resource planning packages to simplify the data input, storage and retrieval processes and overall operation, the data must still be manually entered through a keyboard. Consequently, though it’s less of a hassle, the process remains relatively slow and prone to errors. However, it is now possible to automate the data entry process with a bit of help from a software integration specialist. At the heart of these WMS software solutions is a simple idea first used to identify railway freight cars; a row of vertical black lines known as a barcode.

The use of barcode technology to automate warehouse management systems

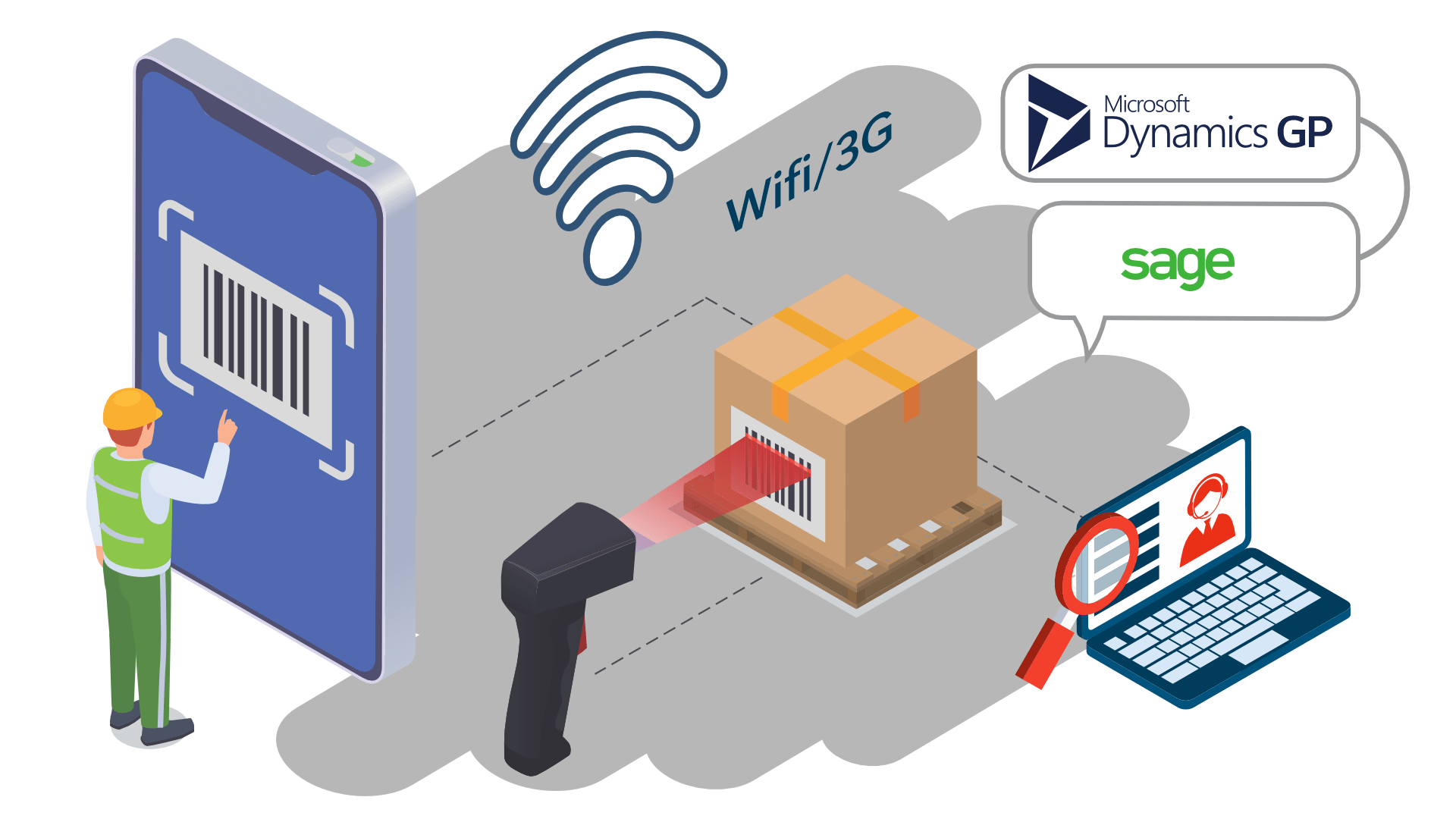

Each stock-keeping unit (SKU) in a conventional warehouse can be identified by its unique alphanumeric code, usually containing at least eight digits. It is far more convenient to input these codes into the system for monitoring purposes than typing a string of lengthy product descriptions. However, misreading a multidigit product code is also far too easy, especially when working under time constraints. By contrast, capturing the bar-coded version of those digits with a hand-held scanner is more accurate and a lot faster. At the till, the scanned barcode data is used to confirm the product description and the price via a digital display. The same barcode scanning technology in the warehouse can be adapted to integrate with the user’s electronic stock records and accounting systems and automatically update them without requiring a staff member to enter product data manually. Our integrated warehouse management systems leverage three main elements as follows:

- A simple, user-friendly software interface: The interface enables seamless integration with various Sage accounting products, Microsoft Dynamics GP, ERP software and other compatible packages.

- High-quality, robust hardware: Choose from our wide range of scanners and printers. By eliminating manual input, your data will be captured instantaneously, and the risk of human error will be minimised.

- Wireless technology: Each time an item is scanned, the associated information is transmitted wirelessly, thus eliminating the need to invest in additional PCs and allowing staff to operate from anywhere within the warehouse premises or exchange data with other branches via a wide area network.

Turnkey warehouse management systems

FenyaSoft has over 20 years of experience developing software integration solutions and tailoring them to meet specific business requirements. Don’t hesitate to contact us to learn more about our WMS software solutions and how they might benefit your operation.

Back to Articles.